You have studied about James Watt's revolutionary

invention. Steam engine could be termed a bellwether. This article aims at

giving chapter and verse on this marvelous invention. You will also read about steam

engine's role in the construction industry.

Introduction

A steam engine is a heat engine that

performs mechanical work using steam as its working

fluid. In simple terms, it uses the expansion principle of chemistry,

where heat applied to water evaporates the water into steam, and the

force generated pushes a piston back and forth inside a cylinder. This pushing

force is typically transformed, by way of a connecting

rod and flywheel, into rotational force for work. The

term "steam engine" is generally applied only to reciprocating

engines as just described, not to the steam turbine.

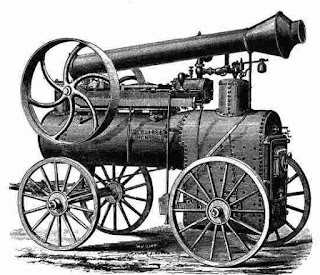

Image Source - Farm Collector

Going

off on a tangent, when it comes to construction industry, construction equipment have to be

infallible. This industry has witnessed a plethora of changes and has undergone

transformation. Therefore, the main pieces of clobber have to match the pace to

deliver unparalleled results. Single girder crane manufacturer SGF Fab is

a giant in the construction equipment

industry. These log handling crane manufacturers have established an

irreproachable name for themselves by affording top-hole equipage.

SGF Fab

provide infallible cranes, material handling equipment, and industrial

fabrications that escalate a gamut of activities. What distinguishes these grab manufacturers in

India is their service of tailor-made equipage. Businesses/clients can

customize equipment according to a site's or job's necessity. SGF Fab is not

merely a company but an organization driven by a strong, resounding set of

values. They will provide assistance 24*7, and their staff is skilled. Moreover,

they not only provide the aforementioned gamut but also fabrication materials and material handling equipment.

In the

Construction Industry

Until the 19th century and into

the early 20th century, heavy machines were drawn under human or animal power.

The work wasn't carried out mechanically.

With the advent of portable

steam-powered engines, the combine

harvester superseded the drawn machine precursors. During the 20th

century, internal-combustion engines became the major power source of

heavy equipment. Kerosene and ethanol engines were used,

but today diesel engines are dominant. The early 20th century

also saw new electric-powered

machines such as the forklift.

Fundamentals

Steam engines are external combustion

engines where the working fluid is separated from the combustion products.

In its thermodynamic cycle, water is heated and changes into steam in a boiler

operating at a high pressure. Work is carried out mechanically when pistons or

turbines are expanded. The reduced-pressure steam is then exhausted to the

atmosphere, or condensed and pumped back into the boiler.

In general usage, the term steam engine can

refer to either complete steam plants (including boilers) such as

railway steam locomotives and portable engines, or may refer to

the piston or turbine machinery alone, as in the beam

engine and stationary steam engine. However, a more detailed look at

the steam locomotive referred to the engine as only that part where the heat in

the steam was turned into motion of the piston, and hence enabled separate

statements for boiler efficiency and engine efficiency. Specialized devices

such as steam hammers and steam pile drivers are dependent

on the steam pressure supplied from a separate boiler.

History

The use of boiling water to produce mechanical

motion goes back over 2,000 years, but early devices were not practical. The

Spanish inventor Jerónimo obtained a patent for a rudimentary

steam-powered water pump in 1606. In 1698 English engineer Thomas Savery patented

a steam pump that used steam in direct contact with the water being pumped.

The atmospheric

engine created by English inventor Thomas Newcomen was

the first commercial true steam engine using a piston, and was used in 1712 for

removing flood water from a mine.

In 1781 Scottish engineer James

Watt patented a steam engine that produced continuous rotary

motion. Watt's ten-horsepower engines enabled a wide range of

manufacturing machinery to be powered. The engines could be sited anywhere that

water and coal or wood fuel could be obtained.

Reciprocating piston type steam engines remained

the dominant source of power until the early 20th century, when advances in the

design of electric motors and internal combustion

engines gradually resulted in the replacement of reciprocating (piston)

steam engines in commercial usage, and the ascendancy of steam turbines in

power generation. Considering that the great majority of worldwide

electric generation is produced by turbine type steam engines, the "steam

age" is continuing with energy levels far beyond those of the turn of the

19th and 20th century.

Steam engines can be said to have

been the moving force behind the Industrial Revolution and saw

widespread commercial use driving machinery in factories, mills and mines;

powering pumping stations; and propelling transport appliances such as

railway locomotives, ships, steamboats and road vehicles. Their use

in agriculture led to an increase in the land available for cultivation. There

have at one time or another been steam-powered

farm tractors, motorcycles (without much success) and

even automobiles as the Stanley Steamer.

Components

and Accessories

There are two fundamental components of a steam

plant: the boiler or steam generator, and the "motor

unit", referred to itself as a "steam engine". Stationary

steam engines in fixed buildings may have the boiler and engine in

separate buildings some distance apart. For portable or mobile use, such

as steam locomotives, the two are mounted together.

Additional Components

Pumps

(such as an injector) used to supply water to the boiler during operation,

condensers to re-circulate the water

and recover the latent heat of vaporization, and super

heaters to raise the temperature of the steam above its

saturated vapor point, and various mechanisms to increase the draft for

fireboxes. When coal is used, a chain or screw stoking mechanism and its drive

engine or motor may be included to move the fuel from a supply bin (bunker) to

the firebox.

(With inputs from

v

Wikipedia

v

This model

was built by Samuel Pemberton between 1880-1890.

v

American Heritage Dictionary of the English

Language (Fourth ed.). Houghton Mifflin Company. 2000.

v

Davids, Karel & Davids, Carolus A.

(2012). Religion, Technology, and the Great and Little Divergences: China

and Europe Compared, C. 700-1800.

v

Preston,

Eric James (2012). Thomas

Newcomen of Dartmouth and the Engine That Changed the World. Dartmouth

History Research Group.

v

Hills

1989, p. 63.

v

Hills

1989, p. 223.

v

Wiser, Wendell H. (2000). Energy resources:

occurrence, production, conversion, use. Birkhäuser. p. 190.

v

Ahmad

Y Hassan (1976). Taqi al-Din

and Arabic Mechanical Engineering, p. 34–35. Institute for the History

of Arabic Science, University of Aleppo.

v

Benett, Stuart (1986). A History of Control

Engineering 1800-1930. Institution of Engineering and Technology. )

Comments

Post a Comment